background

Many resin pellets absorb moisture from the air due to their polymer structure and various functional groups. If molding is performed under conditions of high moisture content, various problems may occur depending on the type of resin, such as the generation of silver streaks and bubbles, and a decrease in mechanical strength due to hydrolysis.

Therefore, most resin pellets require drying before molding, and Dryer is used. We sell a variety of Dryer including the DFC series dehumidifying Dryer, and are compatible with various drying conditions based on the recommendations of resin material manufacturers.

Theme

Regardless of the drying conditions, it is desirable to control the condition of the material just before molding to check whether it is being dried properly on a daily basis at the actual molding site. However, the drying condition of the molded product is often indirectly estimated from the quality of the product after molding.

Ideally, it would be useful from the perspective of traceability to sample and store dried pellets at appropriate times and measure the moisture content of the sample pellets periodically. Alternatively, if a molding defect occurs, pellets could be quickly taken from the line and their moisture content measured, but this can be difficult for the following reasons:

- There is no part on the line where the pellets can be easily removed after drying.

- When collecting pellets from the material extractor under the drying hopper, the pellets fly out with force and scatter around the floor.

Therefore, Kawata has developed a pellet sampling device to easily and quickly extract pellets from the line after drying.

Explanation of this device and how to use it

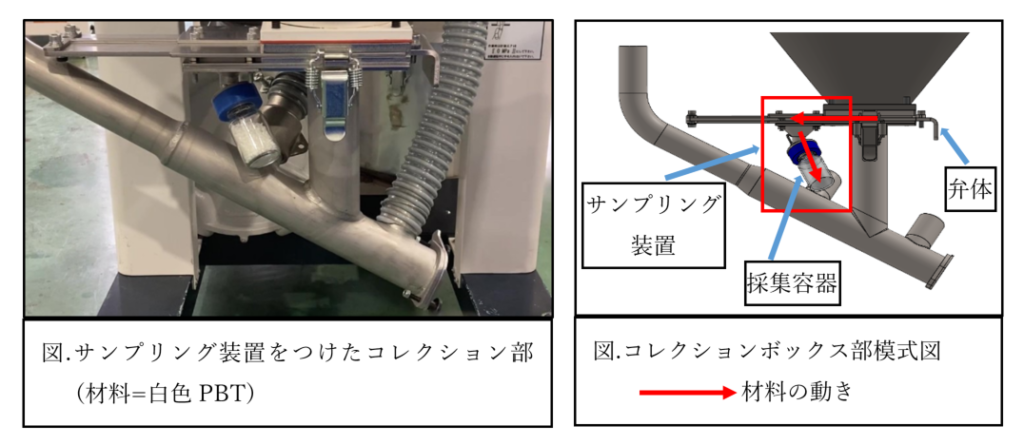

This device is used as a retrofit to the slide gate at the bottom of Kawata's standard drying hopper as shown in the photo below. We use commonly available glass bottles (PS-4K) as collection containers.

The mechanism is very simple. When the valve disc is moved to the left in the figure, the material in the drying hopper moves along the red → and is transported to the collection container.

The usage steps are as follows:

① Open and close the slide gate several times until about 80% of the pellets are accumulated in the collection container.

② Remove the collection container from the sampling device.

③ To prevent outside air from entering, store the collection container with a lid and seal.

④Attach the next collection container.

This completes the first procedure.

This makes it possible to store information on the daily drying condition of the pellets.

Feature

- It is possible to attach bottles of generally available standards.

・Can be retrofitted to existing Kawata slide gates

- Uses a mechanism that makes it easy to open and close the slide gate

- It is possible to create devices with apertures that match other collection containers.

lastly

We have a rental pellet sampling device that is compatible with the DFC series Dryer (loading capacity 25-300 kg), so please feel free to contact us.