カワタは、1935年の創業以来、あらゆる粉体・粒体産業に貢献してきた実績・経験に加え、 実機での各種テストによって、定量的で最適な条件を見出します。

また、お困りの材料でも計画→テスト→検証を繰り返し解決できるシステム、ご安心頂ける提案を致します。

お客様持ち込みのテスト材でのテストも実施可能ですので、是非ご相談ください。

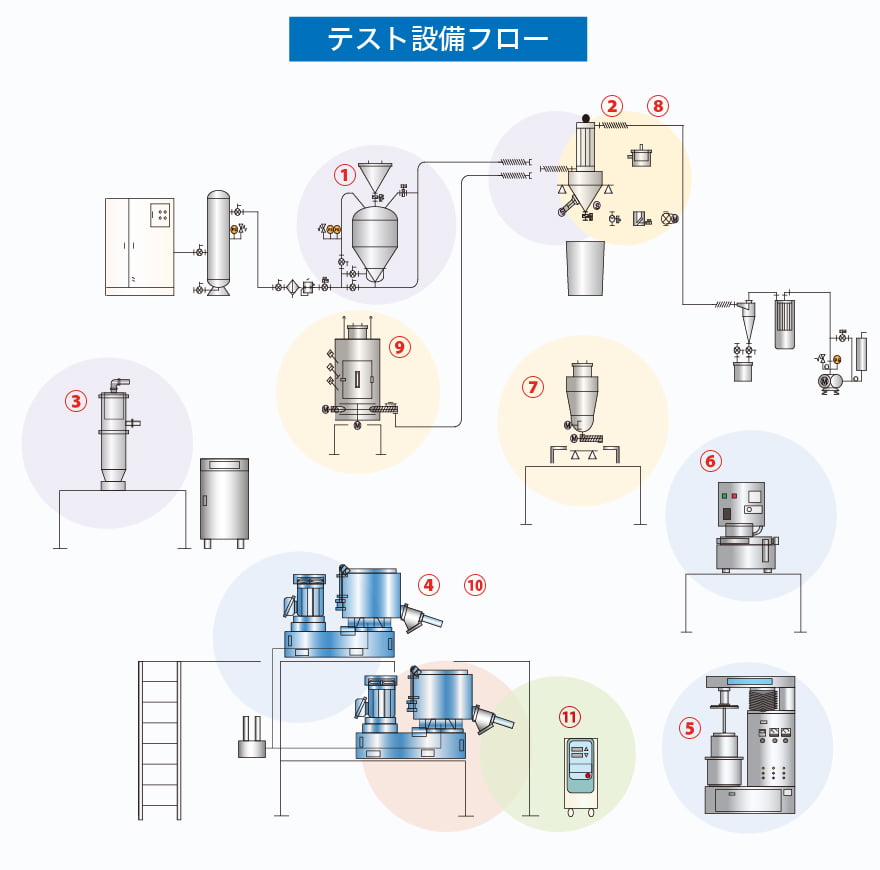

粉体テストエリア POWDER TEST AREA

所在地:テクニカルセンター

セラミックス,電池材料,食品・添加物,プラスチック,医薬品,染料・顔料,カラートナー,粉末金属, フェライト,化粧品,農薬原料,ゼオライト etc….あらゆる粉体のテストを実施できます。

運ぶ

- ① ブロータンク 仕様:40kg/B

- 圧送にて低速・高密度で 材料に優しい 輸送ができます。

- ② 吸引式輸送装置 仕様:40kg/B

- 吸引輸送にて簡易粉体輸送を行います。

- ③ パウダーローダー 型式:VP/VE-20 仕様:20Lr

- 廉価版で手軽な輸送に最適。ブロア仕様とエジェクタ仕様(コンプレッサー)の2機種から選択できます。

混ぜる

- ④ スーパーミキサー 型式:SMV-** 仕様:10,20,100Lr

- 短時間で均一な 高速流動混合ができます。

- ⑤ スーパーフローター 型式:SFC-50C 仕様:10,20,50Lr

- 三次元混合により省エネ、袋に入れたまま混合するので飛散がなく、清掃性にも優れています。

- ⑥ ピッコロ 型式:SMP-2 仕様:1.8Lr

- コンパクトな卓上タイプの高速混合機です。

計る・貯める

- ⑦ ロスイン式連続供給機>

-

普及型仕様 max100kg/hr

減算式計量で高精度な計量をします。

微量計量型仕様 1.0~20cc/min

超微量な供給を高精度で安定供給します。

- ⑧ オートスケール 仕様:40kg/B

- 輸送も兼ねた計量機で輸送しながら計量します。

- ⑨ ノンブリッジフィーダー仕様:200Lr

- ブリッジの発生しやすい粉体でも安定供給可能です。

乾かす

- ⑩ ミキサー+温調機

- 混合しながら昇温させることにより、水分や揮発分を除去できます。

調える

- ⑪ ジャケット温調

- 高精度な温度管理やプログラム温調機能が可能です。 媒体:水用、油用

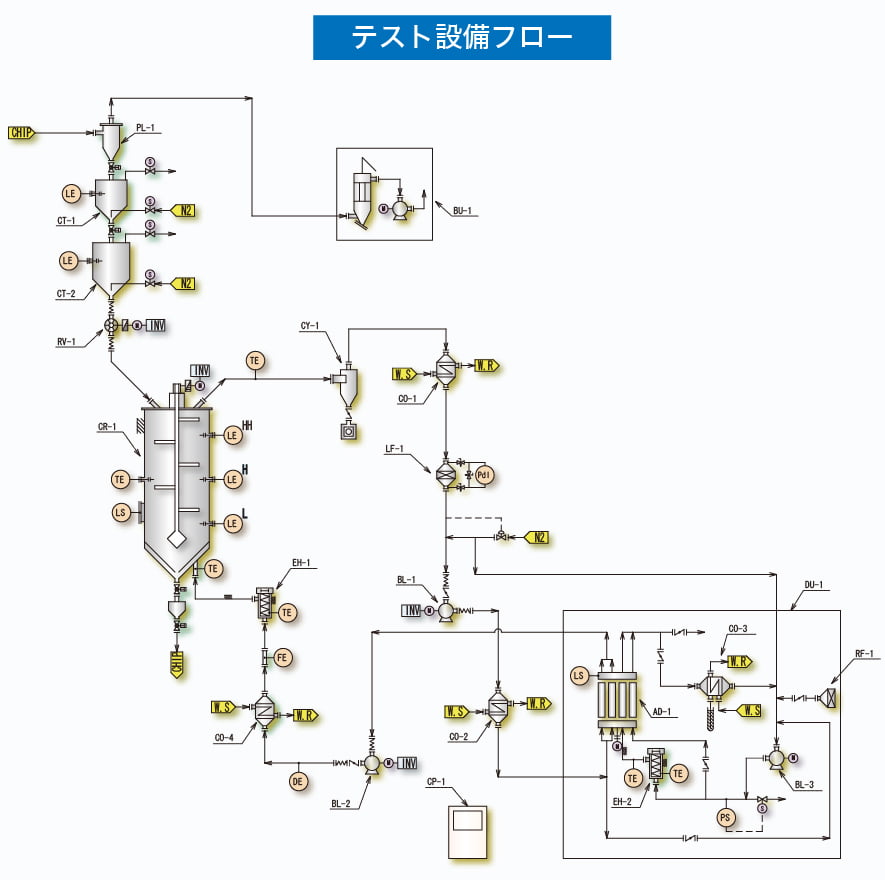

大型乾燥機テストエリア LARGE DRYER TEST AREA

所在地:テクニカルセンター

お客様の材料持込による各種乾燥テストに対応可能な、大型の結晶乾燥テスト施設を常設しています。

- 新規開発材料の乾燥条件を確率したい。

- 熱融着・ブロッキングが発生しやすい材料を低温&低露点乾燥したい。

- 酸化劣化・黄色等を防止する必要があり、N2循環で評価したい。

- 共重合チップを融着・変形させる事なく、安定して結晶させたい。

・・・等々、多様なご要望にお答えします。

水分測定装置(カールフィッシャー法)、示差熱分析装置等の計測機器も完備し、 各種乾燥テストが実施出来る、充実のテスト体制を構築しています。

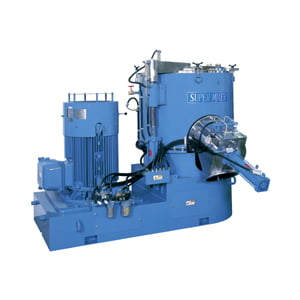

ミキサーテストエリア MIXER TEST AREA

スーパーミキサーはオリジナル設計された攪拌羽根を組み合わせ、高速回転することによって理想的な

流動運動を起こし、様々な素材を短時間で均質な混合分散を可能にしました。

混合・分散・造粒・粉砕・乾燥・コーティング・含浸・表面処理等にワイドな効果を得ることができます。

テスト機としては従来の100L高速ミキサーに加え、500L高速ミキサーを新たに用意いたしましたので

より実ラインに近いテストが可能になりました。テスト機は以下のタイプを用意しております。

- 高速流動混合用

1.8L、10L、20L、100L、500L - 高効率乾式分散

1.5L、100L - 冷却混合

100L、500L - 高速浮上混合

10L 20L 50L

標準機テストエリア STANDARD EQUIPMENT TEST AREA

カワタは、様々なプラスチック材料に対応すべく、標準機器を開発し取り揃えています。乾燥機、配合機、輸送機、粉砕機、etc,

また、射出成型機も設置しておりますので、お客様のニーズに応じたテストを行うことが可能です。